Colour Blindness Testing for Drivers: What You Need to Know

Driving is all about vision. Spotting a hazard, reading road signs, reacting to flashing lights—it all relies on being able to see clearly and accurately. But what happens when someone sees colours differently?

Colour blindness affects roughly 1 in 12 men and 1 in 200 women. Many people don’t even realise they have it. For the average driver, it might not be a huge deal. But for someone who drives for a living—like a delivery driver, HGV operator or bus driver—it can make a big difference.

This is especially true when identifying brake lights, traffic signals or safety markings. Even small mistakes can have serious consequences on the road. That’s why it’s important for fleet managers and occupational drivers to understand how colour vision issues can impact driving and what they can do about them.

This article walks through everything they need to know, from how testing works to what UK regulations say about it. No fluff—just facts, guidance and a few helpful tips.

1. Understanding the Impact of Colour Vision Deficiency on Driving

Not all colour blindness is the same. Some people struggle to tell red from green. Others might find blue and yellow confusing. And in rare cases, someone might barely see colour at all.

When it comes to driving, red-green deficiency is the one that tends to matter most. It can make it hard to tell when a light’s on red or green. It can even make it tricky to see things like hazard signs or brake lights, especially in poor weather or at night.

For occupational drivers, those split-second decisions matter. Confusing red for amber or missing a warning sign could put lives at risk. Fleet managers should take this seriously, not as a reason to panic, but as a reason to be proactive.

After all, the goal isn’t to catch someone out. It’s to make sure every driver on the road has what they need to drive safely and confidently.

2. Real-World Problems That Colour Blind Drivers Might Face

Colour blindness doesn’t affect eyesight sharpness. But it does mess with how colours are seen and separated. That can lead to more mistakes behind the wheel, especially when the road gets busy or stressful.

Here’s the sort of stuff that can go wrong:

- Misreading traffic lights, especially in bright sunlight.

- Failing to notice warning signs that rely on colour.

- Mistaking flashing hazard lights for standard lights.

- Struggling with coloured dashboard indicators.

It’s not just about lights and signs either. Some drivers might have trouble reading maps with colour-coded routes or checking digital displays on newer vehicles. For anyone who drives long shifts or operates under pressure, these small gaps in perception can cause big problems.

A driver might not even notice these challenges until they’re pointed out. That’s why early screening and awareness are so important.

3. How Colour Vision Is Tested During Driver Assessments

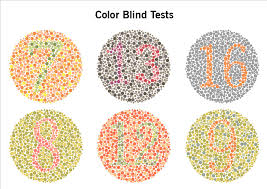

Testing for colour blindness is simple and non-invasive. It’s usually done through one of a few standard methods, like the Ishihara plate colour blind test, where drivers are asked to read numbers hidden in a pattern of coloured dots. If someone can’t spot the numbers, it might suggest a form of colour vision deficiency.

For vocational drivers, this sort of check is often included in a medical exam before getting a Group 2 licence. During the D4 medical, a colour blindness test may be performed to confirm that the driver’s colour recognition skills meet minimum safety standards.

The point isn’t to fail anyone. In most cases, a mild deficiency won’t stop someone from getting behind the wheel. But knowing there’s an issue gives drivers a chance to adjust. It also helps managers match tasks to the right people and avoid unnecessary risks.

Some fleets go beyond the basic check and include colour vision screening in their onboarding or annual medicals. It’s a small step that can prevent big problems down the line.

4. UK Guidelines and Legal Considerations for Commercial Drivers

In the UK, the rules around colour blindness and driving are fairly relaxed, at least for private cars. For Group 1 licence holders, there’s no legal requirement to report a colour vision issue unless it’s affecting safety. Most people with colour blindness can drive just fine.

But for professional drivers, especially those holding a Group 2 licence (like lorry or bus drivers), things are a bit stricter. The DVLA expects these drivers to meet higher medical standards. That includes having adequate vision to identify signals, signs and hazards clearly.

Colour blindness alone doesn’t usually disqualify someone. But if it’s severe enough to interfere with recognising traffic signals or safety signs, further assessment might be needed.

Fleet managers should be aware of these rules, not just from a legal standpoint, but to protect their teams and their reputation. If an accident happens and the driver is known to have a vision issue, the employer could be held responsible, especially if there was no policy in place to manage the risk.

The takeaway? Don’t ignore it. Check it. Track it. And make sure everyone on the road is fit for the job.

5. Fleet Management: Why Testing Matters

When you’re managing a team of drivers, every detail counts. One missed sign, one moment of confusion at a red light—it doesn’t take much for a small issue to become a serious one. That’s why colour vision testing isn’t just a medical formality. It’s a smart move for safety.

Fleet operators are responsible for the health and performance of their drivers. That includes making sure everyone behind the wheel can see what they need to see. If someone’s colour vision isn’t up to scratch, they might still be able to drive—but only with the right adjustments and awareness.

Testing helps managers:

- Spot potential problems early.

- Assign vehicles or routes that match the driver’s needs.

- Reduce liability in case of an incident.

- Keep insurance providers happy by showing risk is under control.

Some companies also use testing as part of their recruitment process. Better to know from the start than face a headache later on. It’s all about being proactive, not reactive.

6. Boosting Road Safety Through Training and Awareness

A test can highlight a problem. But it’s awareness that really makes the difference.

Many drivers with colour vision issues find ways to adapt over time. They learn to rely on position, shape or patterns rather than colour. Still, it helps to back that up with proper training, especially when the roads are busy or unfamiliar.

That’s where a driving safety awareness course can come in. It’s not just about teaching the rules of the road. These courses often dive into human factors, like how distractions can affect driving.

7. Practical Tips for Drivers and Fleet Operators

Here’s the simple stuff that makes a big difference.

For drivers:

- Get your eyes tested regularly—even if you’ve passed before.

- Be honest with your employer about any changes in your vision.

- Learn to rely on more than colour—use position, symbols and road layout too.

For fleet managers:

- Include vision checks in routine health assessments.

- Keep records up to date and easy to access.

- Talk to your drivers. Create a space where they feel safe bringing up concerns.

A little communication can go a long way. So, can a reminder that safety isn’t just about rules—it’s about real people on real roads.

8. Conclusion

Colour blindness isn’t rare. It’s not dangerous on its own. But in the world of professional driving, even the smallest disadvantage can lead to big consequences if left unchecked.

By understanding what colour vision deficiency looks like, how it affects driving and what to do about it, both drivers and fleet managers can keep their roads—and their reputations—safe.

In the end, it’s all about staying informed, paying attention and never underestimating the power of good vision.